Smoky Mountain Model Works, Inc.

Asheville, North Carolina • USA

Asheville, North Carolina • USA

Creating 20th Century Models Using 21st Century Technology

Smoky Mountain Model Works, Inc. • Asheville, NC 28805

Ph.: (828) 777-5619 (10-5 M-F) • Email: jimking3@charter.net

Ph.: (828) 777-5619 (10-5 M-F) • Email: jimking3@charter.net

Design - 3D Printing - Urethane Castings

Advancements in Rapid Prototyping, specifically 3D printing systems and resins, provide an economical means for inventors and modelers to see their designs become reality.

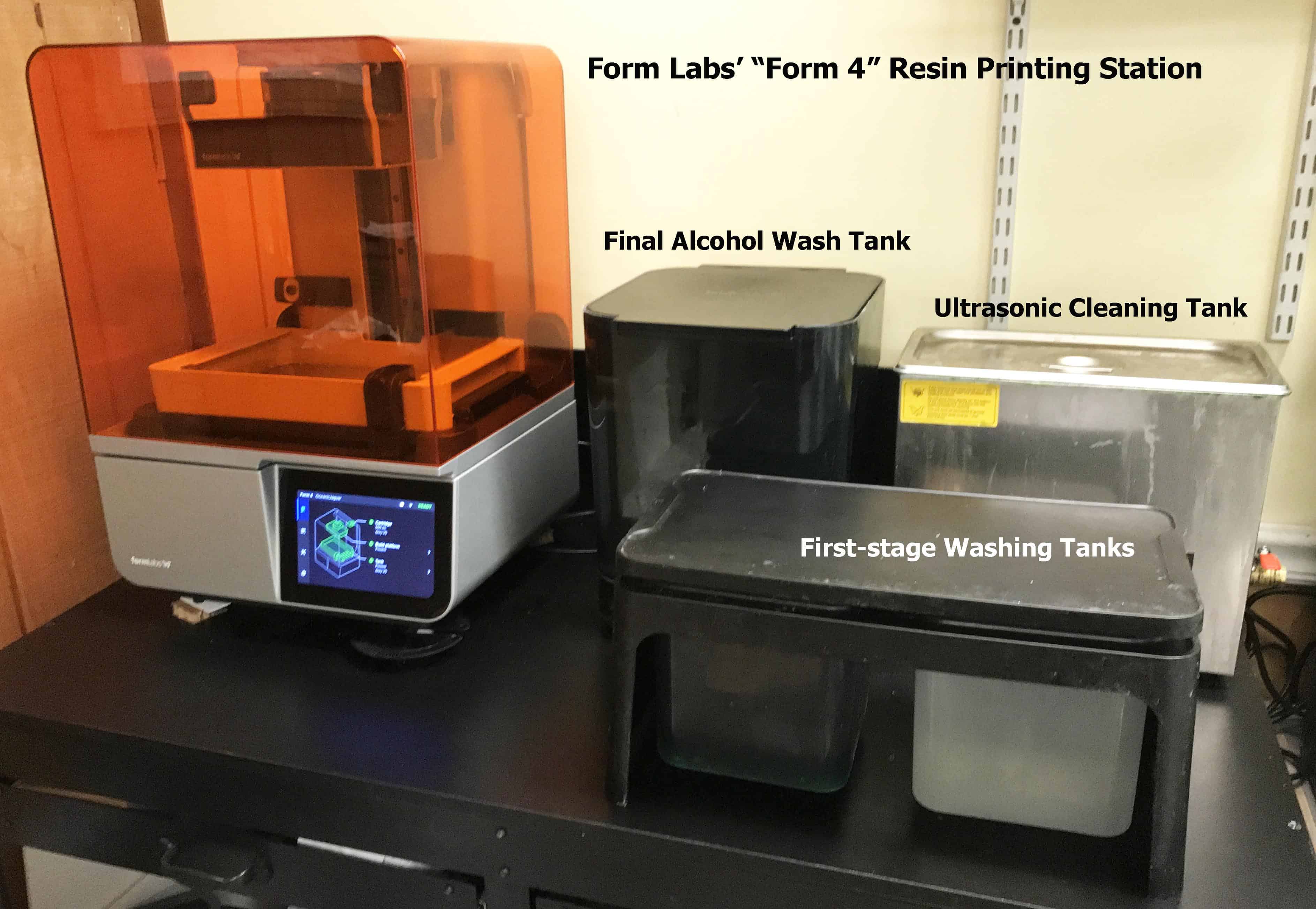

Smoky Mountain Model Works, Inc. uses a Formlabs "Form4" resin printing system (shown above). In addition to 3D Solidworks CAD and cast urethane services, we can now print parts from YOUR .stl or .obj file or create files based on your information. New urethane resins have properties that surpass many injection molded materials ... in Shore A and D scales.

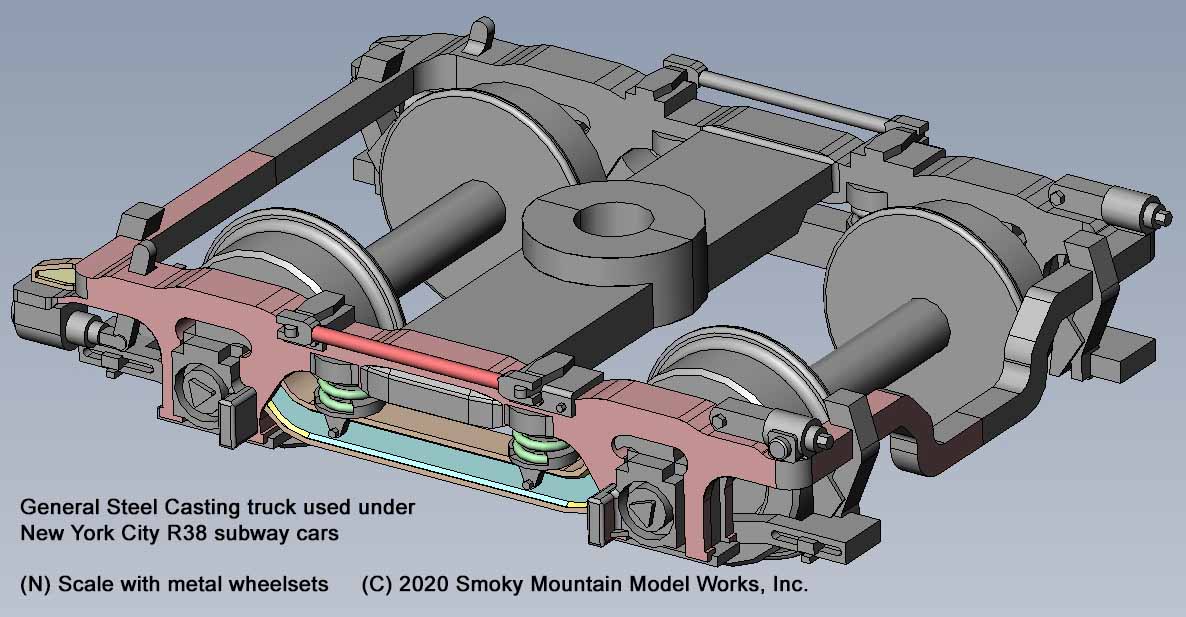

An example of turning a prototype into a FUNCTIONAL model is shown below: a New York City R32 subway car truck that, until recently, only existed in 1:1 scale. It now exists in 1:160 scale and can be "upsized" to other scales with minor modifications to the "N" scale CAD files.

Smoky Mountain Model Works, Inc. uses a Formlabs "Form4" resin printing system (shown above). In addition to 3D Solidworks CAD and cast urethane services, we can now print parts from YOUR .stl or .obj file or create files based on your information. New urethane resins have properties that surpass many injection molded materials ... in Shore A and D scales.

An example of turning a prototype into a FUNCTIONAL model is shown below: a New York City R32 subway car truck that, until recently, only existed in 1:1 scale. It now exists in 1:160 scale and can be "upsized" to other scales with minor modifications to the "N" scale CAD files.

Not all parts require 3D CAD and 3D printing. The production pipe bushings were created from a single, machined, Delrin (R) pattern (including threads) and cast in tinted urethane. Making copies from a part that's long-ago out of production, such as the bicycle pedals and vintage "Muscle Car" parts, is a great way to minimize cost for short-run, reproduction projects.

Contact us to discuss YOUR next product idea.

Contact us to discuss YOUR next product idea.

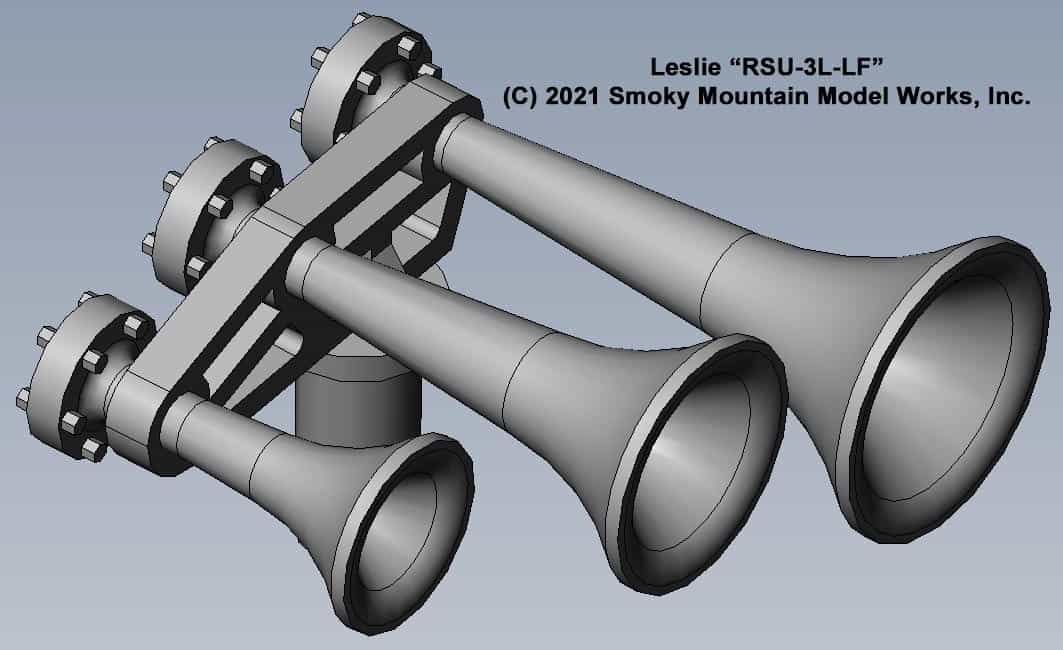

"Leslie" air horn designed from basic sketches and photos ... hundreds of parts printed in resin for model railroaders.

HO scale "disconnect" log buggy designed from sketches and one photo, (100) printed in grey resin, painted, assembled. RIGHT: New York City elevated rail system column and arched supports designed from field-measurements and photos, then printed.